Innovation

University of Dayton Research Institute (UDRI) continue to pursue advancing ceramic electrolyte coated separator for high safety Li battery. To continue the R&D, UDRI proposed a DLA (battery for UAVs, desired by AFRL) application for potential funding for large-scale production of ceramic coated separator for Li batteries. If successful, UDRI will either transfer the technology to industries as decided by DLA or set-up a UD spin-off company to advance and commercialize this technology for Li-ion and Li-S batteries.

Objective

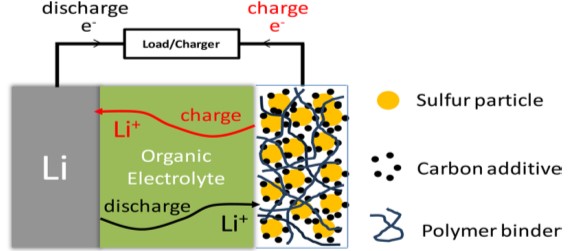

The goal of the project was to develop a rechargeable lithium-sulfur battery (LSB), made with primarily solid components (Li metal as the anode, S-C composite as the cathode, solid-state ceramic electrolyte (SE) coated commercial battery separator (polyethylene, PE) as the separator and organic liquid electrolyte), with energy density > 300 Wh/kg (state-of-the-art, SOA = <225 Wh/kg); cycle life > 100-200 cycles; temperature range of operation 0°C to 100°C (SOA = -12 – 60 °C) as desired by our aerospace customers’ (AFRL and NASA) for their future needs for longer flight range, lighter and safer batteries.

During project duration, multiple (experimental) advancements were made including:

- Thickness of Li metal anode was optimized to match the capacity of S-C cathode

- A promising additive candidate for prolonging the cycle life of a Li|Li symmetric cell were identified

- SE coating separator was employed to achieve 2x better cycle-life of Li-S cell, iv) high capacity (11 mg/cm2) S-C cathodes were developed and used to make industry relevant Li-S cells (both in coin cell and pouch cell format).

The performance achieved at coin cell level indicates that upon large-format Li-S battery fabrication where the weight of all the cell components can be optimized (especially electrolyte weight), a >300 Wh/kg Li-S cell is possible in near future (2-3 years).

Background

OFRN model allowed collaborations to be established between Kumar (University of Dayton) and Akolkar (Case Western Reserve University) who possess complementary expertise in solid-state battery development and testing and understanding the fundamentals of Li electrodeposition, respectively. The OFRN model also allowed collaborations between university, industry (CRG, UES, Xerion) and governments (AFRL, NASA) that enabled winning multiple follow on funding worth >2.5M.

Commercial Goal

UDRI, with the follow-on funding and along with OFRN funding created 4 new jobs (3 existing, 1 joined Tesla motors) and supporting four Ph.D. students. Furthermore, multiple students participated in the research and learned how to further advance this very important energy storage technology, hopefully some of them will be future battery scientists and contribute to increase the Ohio economy, thanks to OFRN funding.