In November 2025, the Under Secretary of War for Research & Engineering announced six new Critical Technology Areas (CTAs) that will guide federal investment and modernization priorities across the defense innovation ecosystem. These CTAs sharpen national focus on the technologies most essential to maintaining U.S. advantage in contested air, space, cyber, and electromagnetic environments:

1. Applied Artificial Intelligence (AAI)

2. Biomanufacturing (BIO)

3. Contested Logistics Technologies (LOG)

4. Quantum and Battlefield Information Dominance (Q-BID)

5. Scaled Directed Energy (SCADE)

6. Scaled Hypersonics (SHY)

For Ohio, this announcement reinforces what the Ohio Federal Research Network (OFRN) has championed since its founding in 2015: applied research aligned to federal mission needs and executed through cross-sector partnerships between universities, industry, and federal laboratories. Furthermore, OFRN’s Areas of Interest (AOIs) directly support the new CTAs, and the program’s current portfolio demonstrates that Ohio is already delivering measurable capability across these domains.

CTA 1: Applied Artificial Intelligence (AAI)

OFRN has funded multiple rounds of projects focused on autonomous navigation, digital engineering, neuromorphic computing, and AI-enabled sensing. Through federal, private, and academic partnerships, OFRN is helping the State of Ohio lead the nation in responsible, mission-ready AI.

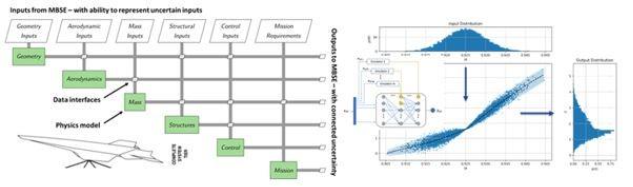

A representative OFRN project is the Machine Learning Framework for Digital Engineering of Hypersonic Vehicles (Figure 1), led by CFD Research Corporation, Air Force Institute of Technology (AFIT), Wright State University, and Air Force Research Laboratory (AFRL). The team developed an ML-supported digital engineering pipeline that produces validated hypersonic vehicle models with quantified prediction uncertainty—significantly improving the reliability of simulations used during early-stage design. This capability shortens development timelines, enhances prediction accuracy in extreme flight regimes, and provides decision-makers with higher-confidence data for risk-informed design and testing.

Figure 1: A machine learning framework for creating digital engineering models of hypersonic vehicles with quantified prediction uncertainty.

CTA 2: Biomanufacturing (BIO)

While BIO is a newer federal emphasis area, OFRN has already funded research that strengthens the foundational capabilities needed for future bio-enabled manufacturing, warfighter health monitoring, and biologically informed decision tools.

One example is the Advanced Cognitive and Physical Sweat Biosensing for Operators project (Figure 2), which is developing next-generation wearable sensors capable of measuring biochemical markers through sweat to assess cognitive load, hydration, fatigue, and stress in real time. Led by the University of Cincinnati, the University of Toledo, and Eccrine Systems in collaboration with AFRL and Naval Medical Research Unit Dayton (NAMRU-D), this work demonstrates how biosensing, materials innovation, and environmental monitoring can converge to improve operator performance and mission readiness. These early investments position Ohio to expand into emerging biomanufacturing applications as the CTA matures.

Figure 2: New technology in sweat devices; new sensors for glucose, urea, and ethanol.

CTA 3: Contested Logistics Technologies (LOG)

OFRN’s work in digital engineering, autonomy, supply-chain modeling, and system-of-systems integration aligns with DoD’s need for resilient, distributed logistics in contested environments. Ohio researchers are developing tools that help commanders sustain operations when supply lines are stressed, disrupted, or under threat.

One example is the Resilient Explainable AI for Casualty Triage & Logistics Awareness project (Figure 3) lead by Mined XAI, The Ohio University, Wright State University, AFRL, NAMRU-D, and National Aeronautics and Space Administration Glenn Research Center (NASA GRC), which advanced AI-enabled decision support for battlefield triage and medical logistics. By combining deep learning, mined causal graphs, and explainable AI techniques, the system provides transparent, trustworthy assessments of casualty severity, resource allocation needs, and evolving logistics constraints. This capability strengthens operational decision-making in degraded, high-tempo environments—improving commanders’ ability to prioritize scarce resources, coordinate evacuation and resupply, and maintain mission effectiveness under contested conditions.

Figure 3: REACT-X and its predictive eXplainable Artificial Intelligence (XAI) platform

CTA 4: Quantum and Battlefield Information Dominance (Q-BID)

OFRN’s portfolio includes leading-edge research in quantum sensing, advanced RF detection, non-cooperative sensing, and next-generation battlefield awareness technologies—core components of achieving information dominance in contested environments.

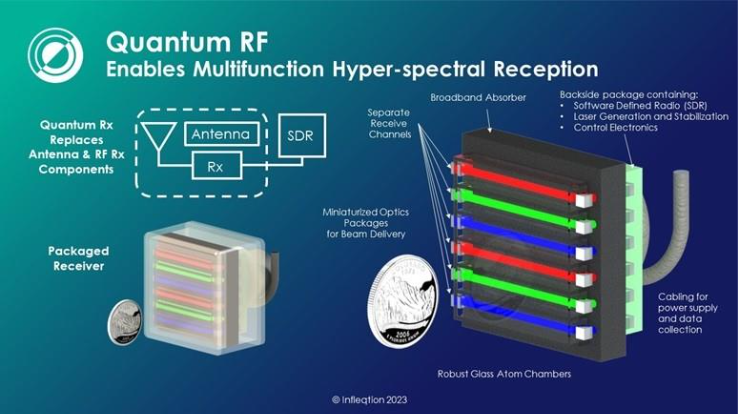

A leading example is the Quantum Sensor System Using Rydberg Atoms project (Figure 4), led by GhostWave, The Ohio State University, University of Dayton Research Institute, Converge Technologies, Infleqtion, and AFRL. This effort integrates Rydberg-atom quantum RF electric field sensors with telecommunications-band wavelength converters and RF noise-radar techniques to create a highly sensitive, broadband quantum sensor system. By enabling detection of weak, covert, or unconventional RF signals that may elude classical sensors, the technology provides a pathway to enhanced threat detection, spectrum awareness, and resilient targeting. These capabilities are central to achieving and maintaining battlefield information dominance across multi-domain operations.

Figure 4: A quantum sensing system, based on the integration of Rydberg atom quantum RF electric field sensors with telecommunications band wavelength converters and RF noise radar systems.

CTA 5: Scaled Directed Energy (SCADE)

Ohio’s expertise in power electronics, thermal management, and advanced aerospace energy systems positions OFRN teams to contribute directly to the high-power, high-efficiency infrastructure required for scalable directed-energy platforms. As directed-energy systems grow in power and operational relevance, they demand fast, accurate, and hardware-representative electrical testing environments.

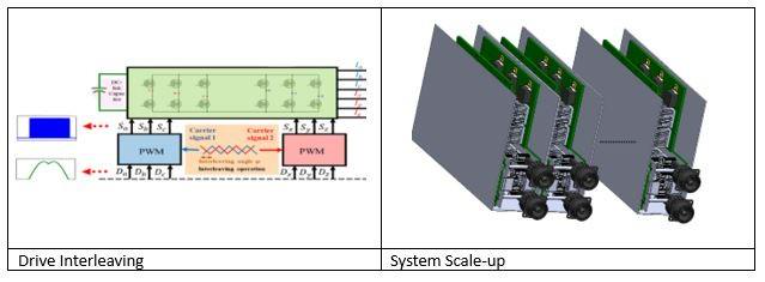

This alignment is demonstrated by the High Bandwidth Light-Weight Modular GaN-Based DC Emulator project (Figure 5), led by the University of Akron, Case Western Reserve University, PC Kraus & Associates, AFRL, and NASA GRC. This effort developed a compact, modular, and bidirectional DC emulator using wide-bandgap GaN technology to support high-fidelity hardware-in-the-loop (HIL) testing. The emulator can rapidly switch between sourcing and sinking power, replicate a wide range of electrical environments, and scale to support larger power architectures. By enabling precise evaluation of power converters, thermal loads, and system behavior under realistic operating conditions, the project provides a critical building block for the advanced power systems needed to field next-generation directed-energy weapons at scale.

Figure 5: Development of a modular and scalable high bandwidth bidirectional DCE that uses a novel parallel interleaved GaN-based DC/DC Dual Active Bridge (DAB) converter topology as the basic building block of the DCE.

CTA 6: Scaled Hypersonics (SHY)

Ohio’s manufacturing strength, materials expertise, and deep aerospace heritage make the state a national leader in advancing scalable hypersonic systems. OFRN-funded research is enabling the development of high-temperature materials, advanced manufacturing processes, digital engineering methods, and system-integration tools required to design, build, and field hypersonic capabilities at scale.

One representative example is the Gradient Alloy Processing in Laser Powder Bed Fusion for Hypersonic Applications project (Figure 6), led by ARCTOS Technology Solutions, Ohio University, the University of Toledo, GoHypersonic, Hyphen Innovations, and NASA GRC. This effort is developed additive manufacturing (AM) techniques that produce gradient alloys capable of withstanding the extreme thermal and mechanical loads experienced during hypersonic flight. By optimizing multi-material laser powder-bed fusion processes, the project enables the fabrication of complex geometries, improved thermal protection structures, and tailored material properties that are difficult or impossible to achieve through traditional manufacturing.

These advances support broader DoD goals to accelerate hypersonic prototyping, reduce component cost, and improve manufacturability. OFRN’s hypersonics alignment also extends beyond materials to include test-range integration, high-fidelity simulation, autonomy-enabled flight systems, and machine-learning-enhanced digital engineering

Figure 6: This project is designed to advance the state of the art in multi-material deposition for hypersonic applications and simultaneously drive expertise in multi-material solutions

Why This Matters for Ohio — and for the Nation

OFRN’s alignment to the new CTAs is not aspirational; it is operational.

Furthermore, OFRN’s competitive funding and transition-focused model ensures that Ohio’s research ecosystem is:

Delivering capabilities directly relevant to DoD R&E priorities

Accelerating transition through co-development with AFRL, National Air and Space Intelligence Center (NASIC), NASA GRC, NAMRU-D, and the Ohio National Guard

Strengthening the domestic industrial base by growing Ohio’s tech companies and supply chain

Building a high-skill workforce prepared for the nation’s most critical missions

As the federal government sharpens its technology focus, OFRN ensures Ohio is not just aligned—but leading.

###

About Parallax Advanced Research & Ohio Aerospace Institute

Parallax Advanced Research is a research institute that tackles global challenges through strategic partnerships with government, industry, and academia. It accelerates innovation, addresses critical global issues, and develops groundbreaking ideas with its partners. With offices in Ohio and Virginia, Parallax aims to deliver new solutions and speed them to market. In 2023, Parallax and the Ohio Aerospace Institute (OAI) formed a collaborative affiliation to drive innovation and technological advancements in Ohio and for the Nation. OAI plays a pivotal role in advancing the aerospace industry in Ohio and the nation by fostering collaborations between universities, aerospace industries, and government organizations and managing aerospace research, education, and workforce development projects.

About the Ohio Federal Research Network

The Ohio Federal Research Network has the mission to stimulate Ohio’s innovation economy by building statewide university-industry research collaborations that meet the requirements of Ohio’s federal laboratories, resulting in the creation of technologies that drive job growth for the State of Ohio. The OFRN is a program managed by Parallax Advanced Research in collaboration with The Ohio State University and is funded by the Ohio Department of Higher Education.