Agile Ultrasonics is at the forefront of space technology, developing advanced ultrasonic welding solutions for thermoplastic (TP) composites. As a key player in the "Structural Materials Joining in Space" project, funded by Ohio Federal Research Network (OFRN), Agile is tackling one of the aerospace industry's most formidable challenges: achieving reliable TP composite welding in the harsh, environmental conditions of space. This project is an enabler for in-space manufacturing, servicing, and repair—technologies that NASA and other industry leaders could use for the future of deep-space exploration.

Agile Ultrasonics' expertise extends beyond space applications, with a strong foundation in developing, designing, and manufacturing advanced robotic end effectors for critical polymer composite joining. As Jim Stratton , President of Agile Ultrasonics highlights, the company's cutting-edge technology has been installed in top-tier aerospace and is being evaluated for use in U.S. Air Force, and NASA programs. Agile’s innovations include continuous ultrasonic welding (CUW) without the need for energy directors, film layers, or other inserts—an advancement that enhances efficiency and reliability while expanding material selection options for component designers. Additionally, their solutions enable precise shaping and compacting of high-performance carbon fiber reinforced thermoplastic (TP) composites, supporting both terrestrial and space-based applications.

Overcoming the Challenges of Space Welding

Traditional ultrasonic welding techniques often require additional materials, such as energy directors or resin inserts, which introduce complexities in space where weight and automation are critical concerns. Agile Ultrasonics has developed an innovative solution: Continuous Ultrasonic Welding (CUW) without the need for energy directors or film layer inserts, a process that can be used to eliminate auxiliary materials while ensuring high-performance joints in advanced TP composites such as LM PAEK, PEEK or PEKK prepregs —widely used in aerospace structures.

"The 'Structural Materials Joining in Space' project that Agile has been awarded by Parallax Research seeks to develop baseline ultrasonic welds of TP composites in extreme space conditions. No data is currently known to exist for this type of ultrasonic welding," Stratton explains.

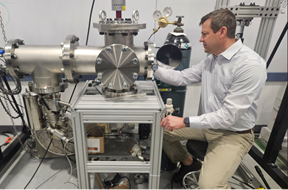

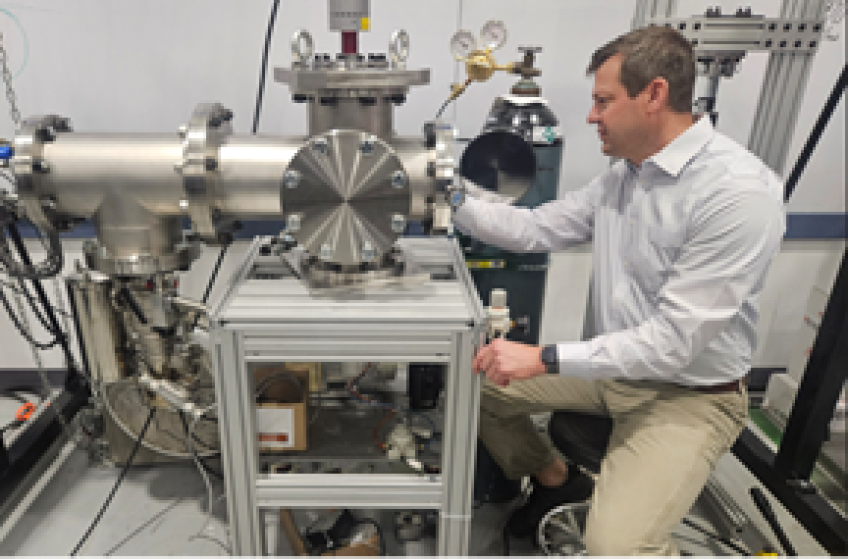

Agile has designed and built a custom vacuum chamber capable of simulating the extreme thermal fluctuations of space, ranging from -190°C to +120°C. This chamber allows real-time, in-weld temperature monitoring using an advanced sensor array that provides critical data to correlate thermal profiles with mechanical strength. These insights are essential for refining welding parameters and ensuring the long-term reliability of TP composite welds in space environments.

Chris Skocik, Agile Ultrasonics Engineering Manager loading the

company’s vacuum chamber in preparation for an ultrasonic weld

trial joining carbon fiber reinforced thermoplastic composites at

the company’s facility in Columbus, Ohio. Source | Agile Ultrasonics

Innovations Transforming Aerospace Manufacturing

Agile Ultrasonics' CUW technology represents a major advancement opportunity in both space-based and terrestrial composite manufacturing. Unlike conventional ultrasonic welding systems, Agile has commercialized its technology as a modular, adaptable robot-agnostic end effector. This flexibility will be crucial for future lunar and deep-space missions, where robotic assembly and repair will be necessary for constructing and maintaining spacecraft structures and habitats.

Stratton elaborates: "Agile created the option of applying this highly adaptable, modular, low-power machine-driven robotic system to structural element manipulation, joining, and repurposing of composite materials on-orbit or on the lunar surface. By correlating weld test data with corresponding weld temperature data, we will advance understanding of the environmental impact on welds as they occur."

Beyond space applications, Agile’s CUW technology has transformative potential for defense and commercial aerospace where the ability to create high-strength, lightweight composite joints, without adhesives or reinforcements, can be a game changer for advanced aerospace structures. Current efforts include maturing the technology to support Advanced Air Mobility (AAM) systems and potentially Autonomous Collaborative Platforms (ACP) for AFRL through Midwestern Regional Network funding.

Industry Collaboration and Commercialization

Agile Ultrasonics' success is built on strategic supply chain partnerships including material and robotic systems makers, tier-one aerospace, NASA, the U.S. Air Force, and top research institutions, including the University of Dayton Research Institute (UDRI), The Ohio State University, Central State University and Oak Ridge National Laboratory. These collaborations are critical in bridging the gap between research and real-world applications.

Support from the OFRN Round 6 program has accelerated Agile’s commercialization efforts, allowing the company to demonstrate its advancements in ultrasonic welding technology to key aerospace stakeholders. The funding has enabled crucial testing, process refinement, and validation studies that strengthen Agile’s position as an industry leader in advanced composite joining.

"OFRN 6 has provided leverage for Agile to grow its existing business with NASA and helped Parallax demonstrate to its funding source that the support Agile has received through OFRN 6 is producing jobs, breakthrough technology, and follow-on programs as proposed at the outset," Stratton notes. "Further, the work being done under OFRN 6 has helped Agile gain traction with the US Agile recently received an award from the Air Force Research Lab (AFRL) Midwest Regional Network to apply its continuous ultrasonic welding of thermoplastic composites to an AFRL funded program."

Shaping the Future of Space-Ready Composites

As Agile Ultrasonics continues to refine its CUW process, its innovations are poised to transform composite manufacturing across space, defense, and commercial aerospace sectors. By advancing NASA’s capabilities for in-space assembly, repurposing and repair, CUW technology plays a vital role in the long-term vision of sustainable space exploration.

"We have worked almost daily with our stakeholders at NASA’s Glenn Research Center in Cleveland, NASA’s Langley Research Center in Hampton, Virginia, and NASA’s Goddard Space Flight Center in Greenbelt, Maryland. We have hosted multiple face-to-face visits at our facility and collaborated extensively on ultrasonic welding projects within and outside of OFRN 6," Stratton emphasized. "Our objective is to advance Agile’s technology so that it becomes an integral part of the supply chain as a go-to platform for joining, shaping, compacting, sealing, or consolidating TP composites. An immense effort will be required to achieve this level of commercial success."

Beyond space, Agile’s innovations are unlocking new opportunities for high-performance composites in aviation, urban air mobility, and defense. With continued collaboration and industry support, Agile is set to define the next era of structural materials joining—both on Earth and in the most extreme environments of space.

###

About Ohio Federal Research Network (OFRN)

The Ohio Federal Research Network (OFRN) has the mission to stimulate Ohio’s innovation economy by building statewide university-industry research collaborations that meet the requirements of Ohio’s federal laboratories, resulting in the creation of technologies that drive job growth for the State of Ohio. The OFRN is a program managed by Parallax Advanced Research in collaboration with The Ohio State University and is funded by the Ohio Department of Higher Education.

About Parallax Advanced Research and the Ohio Aerospace Institute (OAI)

Parallax Advanced Research is a 501(c)(3) private nonprofit research institute that tackles global challenges through strategic partnerships with government, industry, and academia. It accelerates innovation, addresses critical global issues, and develops groundbreaking ideas with its partners. With offices in Ohio and Virginia, Parallax aims to deliver new solutions and speed them to market. In 2023, Parallax and the Ohio Aerospace Institute (OAI) formed a collaborative affiliation to drive innovation and technological advancements in Ohio and for the nation. The Ohio Aerospace Institute plays a pivotal role in advancing the aerospace industry in Ohio and the nation by fostering collaborations between universities, aerospace industries, and government organizations, and managing aerospace research, education, and workforce development projects. More information on both organizations can be found at Parallax and OAI websites.

Air Force Research Lab

AFRL-2025-2496

Distribution Statement A: Approved for Public Release: distribution is unlimited" at the end of the article.