On Friday, September 12, ARCTOS Technology Solutions delivered the final briefing and demonstration for the Ohio Federal Research Network (OFRN)-funded Project “Gradient Alloy Processing in Laser Powder Bed Fusion for Hypersonic Applications,” a groundbreaking effort focused on multi-material additive manufacturing for hypersonic applications. The event, hosted by Ohio University, highlighted not only the technical advancements achieved, but also the strong partnership between ARCTOS and Ohio University, University of Toledo, GoHypersonic Inc., and Hyphen Innovations Inc. — and the critical contributions of thirteen students.

Pushing the State of the Art

Under the supervision of Dr. Radu Pavel, Director of Industrial Innovation at ARCTOS, the project focused on using laser powder bed fusion to create graded alloys—multi-material components that combine heat-resistant exteriors with lighter, structurally efficient interiors. These advanced materials are vital for the extreme environments of hypersonic flight.

“The project itself was designed to advance the state of the art of multi-material deposition,” said Pavel. “We were using laser powder bed fusion to combine different materials in a way that could withstand the harsh environment of hypersonic flight.”

The team successfully fabricated and tested components that demonstrated gradual material transitions, advancing the technology readiness level for future aerospace and defense applications.

For ARCTOS, the project expanded technical capabilities while increasing visibility in the rapidly growing field of graded alloys.

“This helped us further advance the technology that enables us to develop this type of material,” said Pavel. “We designed and fabricated new powder hopper systems, developed software and hardware, and created capabilities we can now leverage for commercial and defense applications.”

The collaborating universities also saw tremendous benefit. Students and faculty gained hands-on access to technology not yet available commercially, broadening curriculum and research in advanced manufacturing.

“This is something entirely new,” Pavel said. “It’s a technology they wouldn’t find commercially. This basically is pushing the envelope, and it helped engage students in cutting-edge research.”

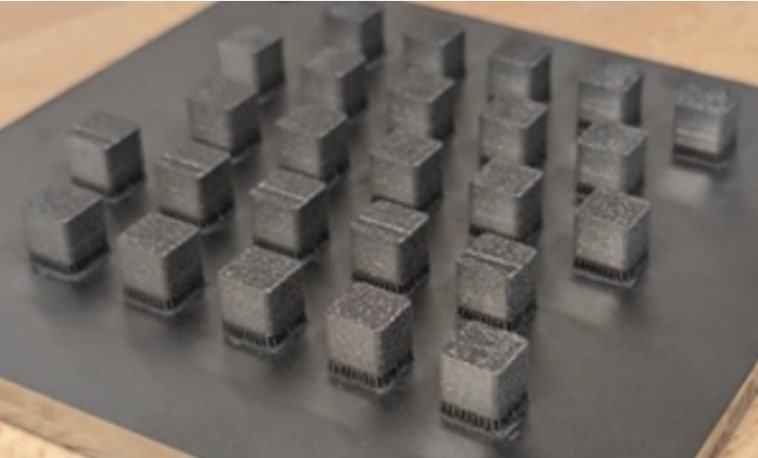

Caption: Test specimens for graded alloy recipe development.

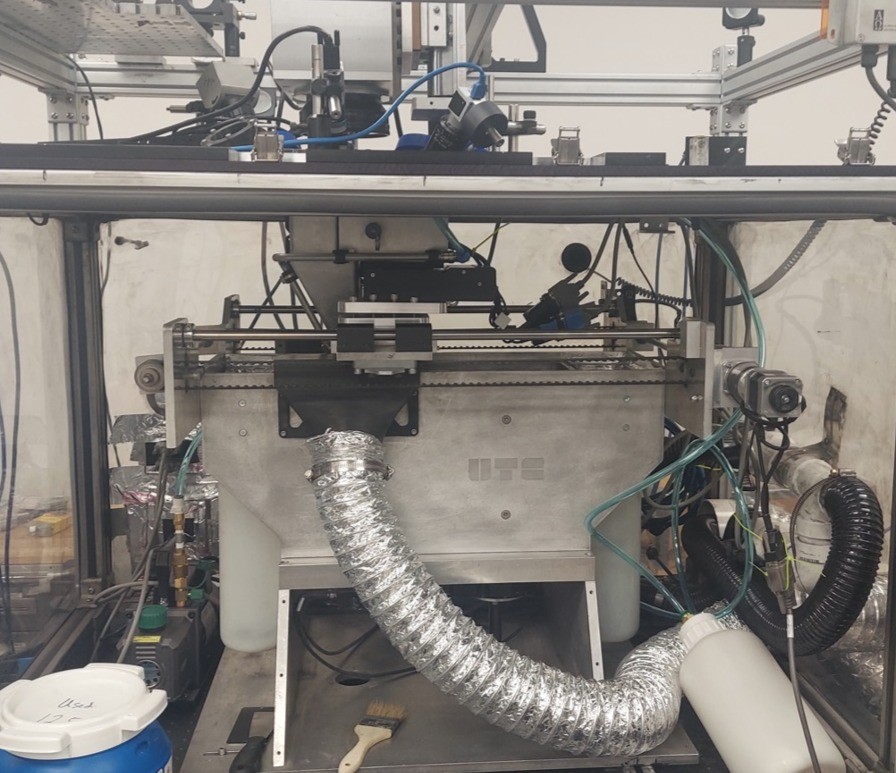

Caption: Hopper system for graded alloys fabrication.

Caption: Laser powder bed fusion testbed at ARCTOS.

The Student Experience

Perhaps the most compelling story of the project lies in the student involvement. Many students worked directly on the machines, fabricated parts, and conducted testing—real-world experience that went far beyond classroom learning.

“Sometimes students learn theoretical things, they see slides in class, and they read books,” said Pavel. “But in this case, they worked on machines. They built the components. Some of them ran the tests. So, it was a hands-on engagement.”

The impact went beyond the lab. With expensive powders and limited resources, students had to balance technical curiosity with economic realities.

“These materials in powder form are very expensive,” Pavel said. “So, you need to be very careful how you plan your experimental work. They got to experience firsthand what it means to plan not just from a technical point of view, but also from the financial point of view.”

For many, the experience proved transformational. Several students secured jobs in the industry after the project, demonstrating the direct workforce impact of OFRN collaborations.

The Role of OFRN Funding

Pavel was clear that none of this progress would have been possible without OFRN support.

“Without this funding, probably we wouldn’t have gotten to this level,” he said. “It required funding and resources that otherwise we, as one company, couldn’t have invested. This gave us the ability to demonstrate technology advancement and get good results.”

The OFRN investment not only enabled this project to succeed but also positioned ARCTOS and Ohio University for future opportunities with defense, NASA, and commercial partners.

As ARCTOS builds on the outcomes of the project, the lessons learned will continue shaping industry-academia partnerships across Ohio.

“Projects like this are very impactful,” said Pavel. “They expose students to new technologies, give professors the chance to advance their teaching, and prepare students for real-world careers right here in Ohio.”

From cutting-edge additive manufacturing breakthroughs to the career trajectories of young engineers, this project demonstrates the power of OFRN funding to bridge small business innovation, academic expertise, and student opportunity—fueling Ohio’s leadership in aerospace and defense.

###

About Ohio Federal Research Network (OFRN)

The Ohio Federal Research Network (OFRN) has the mission to stimulate Ohio’s innovation economy by building statewide university-industry research collaborations that meet the requirements of Ohio’s federal laboratories, resulting in the creation of technologies that drive job growth for the State of Ohio. The OFRN is a program managed by Parallax Advanced Research in collaboration with The Ohio State University and is funded by the Ohio Department of Higher Education.

About Parallax Advanced Research and the Ohio Aerospace Institute (OAI)

Parallax Advanced Research is a research institute that tackles global challenges through strategic partnerships with government, industry, and academia. It accelerates innovation, addresses critical global issues, and develops groundbreaking ideas with its partners. With offices in Ohio and Virginia, Parallax aims to deliver new solutions and speed them to market. In 2023, Parallax and the Ohio Aerospace Institute (OAI) formed a collaborative affiliation to drive innovation and technological advancements in Ohio and for the nation. The Ohio Aerospace Institute plays a pivotal role in advancing the aerospace industry in Ohio and the nation by fostering collaborations between universities, aerospace industries, and government organizations, and managing aerospace research, education, and workforce development projects.