The Future of Space Construction

The Structural Materials Joining in Space project, led by a team at The Ohio State University with support from the Air Force Research Laboratory (AFRL), NASA, and funding from the Ohio Federal Research Network (OFRN), is breaking new ground in developing welding processes for space. As global space initiatives expand, the need to build, maintain, and repair structures in harsh space environments has never been more critical.

This project, aimed at advancing laser welding techniques in microgravity, vacuum, and extreme temperatures, holds the potential to transform the way we construct and maintain future space infrastructure — from repairing spacecraft to building lunar habitats.

Meeting the Challenge of Welding Beyond Earth

While welding is commonplace on Earth, doing it in space presents unique obstacles.

“Welding is a critical manufacturing technology on Earth, but there’s currently no process that’s been fully tested, verified, and qualified for use in space,” said Aaron Brimmer, PhD student on the project. “On Earth, if something metal breaks, you weld it — it’s essentially the hot glue of the manufacturing world. But in space, we need a reliable, proven method to do the same.”

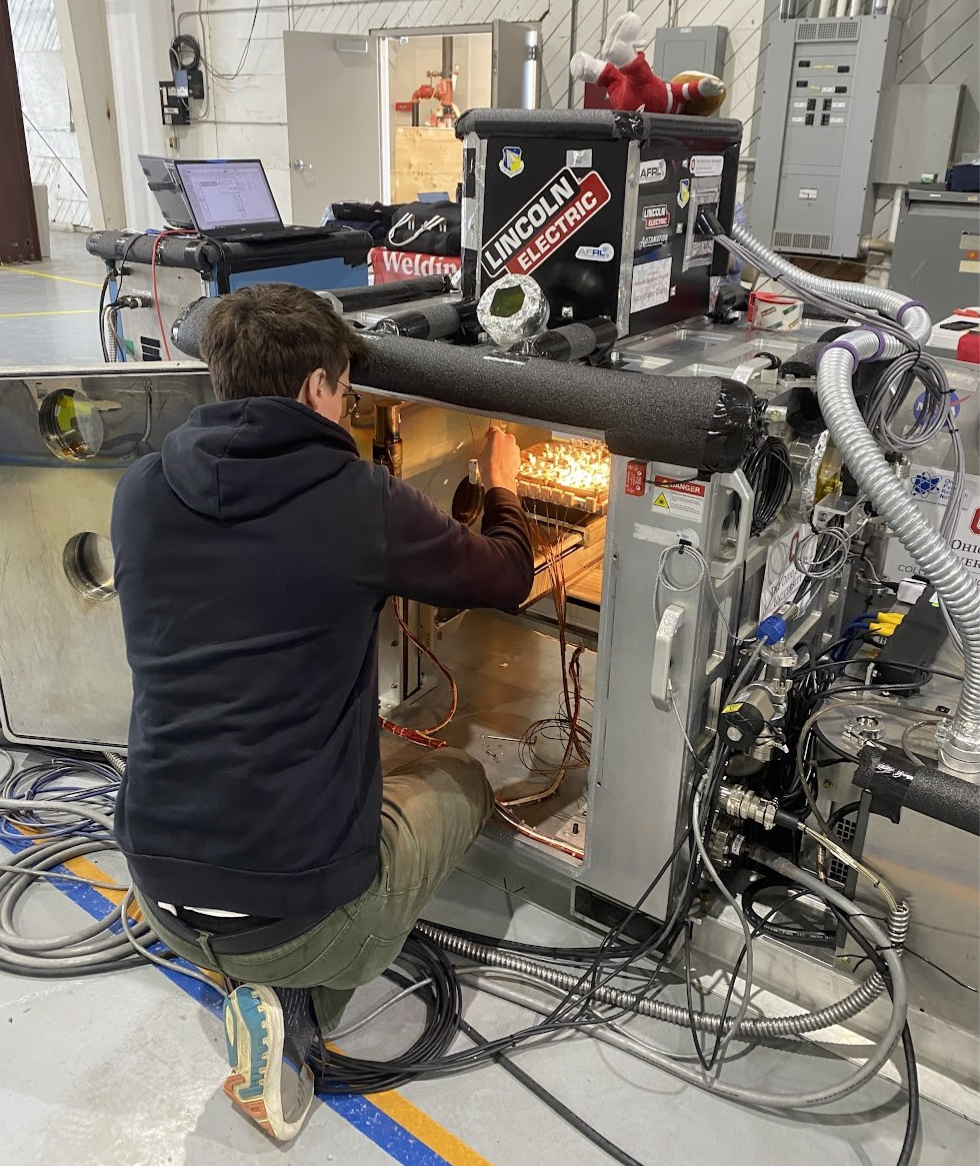

To address this challenge, the Ohio State team focused on laser beam welding — a process that minimizes or eliminates the need for shielding gases, which are impractical to transport into space, while enabling the creation of deep, narrow joints with minimal material distortion.

Their experiments — conducted on board a Zero Gravity Corporation parabolic flight out of Salina, Kansas — simulated the combined challenges of microgravity and vacuum, gathering critical data to understand how welding behaves under these extreme conditions.

High-Stakes Testing and Data Collection

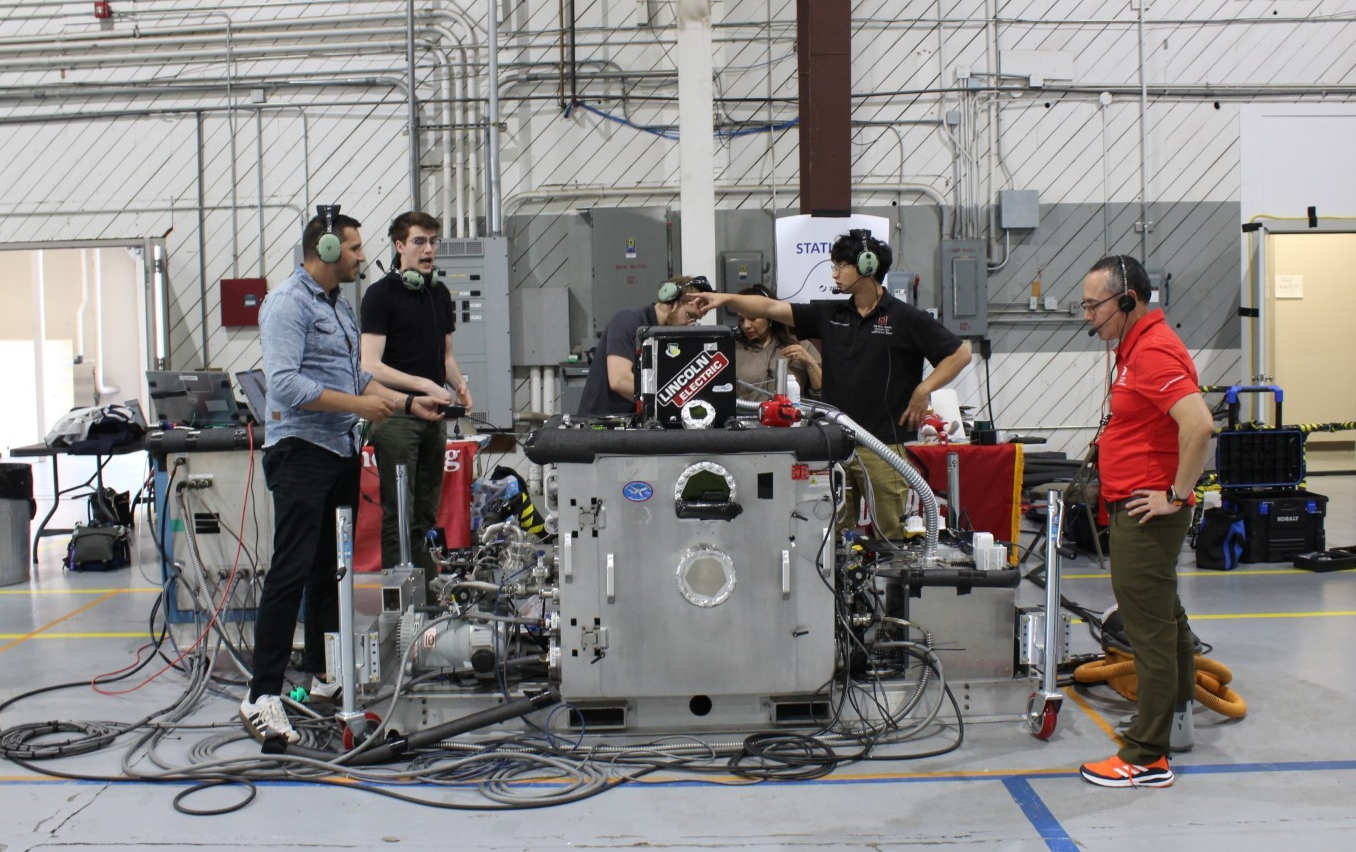

The team’s latest flight was the culmination of several months of preparation. Over a series of 30 parabolas, the researchers performed laser welds on aluminum, titanium, and stainless-steel plates, using onboard cameras, thermocouples, and sensors to capture data in real time.

“These flight campaigns can be incredibly stressful,” said Brimmer. “It takes a tremendous amount of work just to get everything operational — we had been planning this particular mission for at least six months.”

Yet despite the tension, the atmosphere was also electric.

“There was a real sense of excitement,” Brimmer said, “because it’s such a unique and, honestly, privileged opportunity to make a meaningful contribution to space exploration.”

Abigail Harrison, the Starlab Research Lead who recently joined the team to observe the Ohio State group during their tests, said, “The flight itself is relatively short compared to the incredible amount of preparation behind it. The team arrived in Salina about five days before the flight and worked tirelessly each day to ensure the equipment was in good condition and that all necessary testing and preparations were complete. By the time the flight began, they were fully ready to collect high-quality data.”

Moving from Test to Application

This wasn’t the team’s first time in the air — but it marked a big step forward.

“The last flight was focused on testing the equipment, while this flight was about testing the welds,” said Brimmer. “We gathered valuable data from the first flight, but one of our main goals last time was simply to achieve a successful weld. Given how challenging and unpredictable the environment is, we weren’t even sure the setup would work — but it did.”

One standout success from the tests was the exceptional performance of titanium. The team found that titanium delivered the best results among all the materials they tested. Typically, titanium poses challenges due to oxidation, but under high-vacuum conditions, this issue is eliminated, allowing for the creation of clean, high-quality welds.

Beyond testing materials, the team also made hermetic seals, simulating repairs like patching micrometeoroid impacts on spacecraft hulls — work that could one day protect lives on orbiting stations or lunar habitats.

Navigating Challenges and Building Collaboration

While technical hurdles are to be expected, the team also had to navigate logistical snags. When their flight was rescheduled and relocated, they arrived in Kansas only to find the power connections they needed weren’t available. However, they were able to buy the right connector and cords, averting disaster, which was a great relief.

The flight also brought an unexpected benefit: collaboration.

Harrison said, “It felt like a mini conference, where our team and students connected with several other groups involved in space research. Even a former NASA astronaut was present, which sparked meaningful conversations and thoughtful reflections on the many possibilities for collaboration in this field.”

What’s Next: Preparing for Space

Looking ahead, the Ohio State team is preparing for a third research flight, anticipated in October, to perform more advanced tests, including cryogenic and elevated-temperature welding. Additionally, they are planning the next major milestone: deploying the welding system into orbit.

Brimmer said, “Deploying a functional laser welding system in space could be truly revolutionary. We have already engaged with a system integrator and identified a potential location aboard the ISS for its installation. At this stage, our primary focus is securing the necessary funding to move forward.”

Harrison added that this technology represents a doorway that is only just beginning to open. Once fully unlocked, it will dramatically expand what is possible in space, unleashing new capabilities that have the potential to transform the way space exploration is conducted.

Welding: A Critical Tool for the Future

The significance of this work is clear.

As Brimmer said, “Any sustainable presence in space is going to require reliable repair and construction processes, and welding is fundamental to that. Currently, space missions are heavily constrained by both mass and volume limitations. For advanced technologies like nuclear thermal propulsion systems, in-space assembly will be essential.”

Harrison echoed this vision, emphasizing the transformative potential of welding technology in space. She highlighted that future welding engineers will be able to construct structures in orbit that overcome current limitations, enabling more innovative, efficient, and sustainable operations in low Earth orbit. These advancements are expected to provide significant benefits on Earth and play a crucial role in supporting exploration missions to Mars and beyond.

###

About Ohio Federal Research Network (OFRN)

The Ohio Federal Research Network (OFRN) has the mission to stimulate Ohio’s innovation economy by building statewide university-industry research collaborations that meet the requirements of Ohio’s federal laboratories, resulting in the creation of technologies that drive job growth for the State of Ohio. The OFRN is a program managed by Parallax Advanced Research in collaboration with The Ohio State University and is funded by the Ohio Department of Higher Education.

About Parallax Advanced Research and the Ohio Aerospace Institute (OAI)

Parallax Advanced Research is a 501(c)(3) private nonprofit research institute that tackles global challenges through strategic partnerships with government, industry, and academia. It accelerates innovation, addresses critical global issues, and develops groundbreaking ideas with its partners. With offices in Ohio and Virginia, Parallax aims to deliver new solutions and speed them to market. In 2023, Parallax and the Ohio Aerospace Institute (OAI) formed a collaborative affiliation to drive innovation and technological advancements in Ohio and for the nation. The Ohio Aerospace Institute plays a pivotal role in advancing the aerospace industry in Ohio and the nation by fostering collaborations between universities, aerospace industries, and government organizations, and managing aerospace research, education, and workforce development projects.