COLUMBUS, Ohio — Hypersonic flight has long promised faster global reach, reusable space access, and new defense capabilities. Yet one challenge continues to limit real-world deployment: materials that can survive extreme heat repeatedly without adding excessive weight or cost.

At speeds above Mach 5, vehicle surfaces experience aerothermal environments exceeding 3,000 degrees Celsius. Many existing thermal protection systems can withstand those conditions once but degrade quickly under repeated use. Critical components such as flaps, seals, and joints are especially vulnerable, forcing many hypersonic designs into a single-use model that limits affordability and operational readiness.

A new Ohio-led research effort aims to change that.

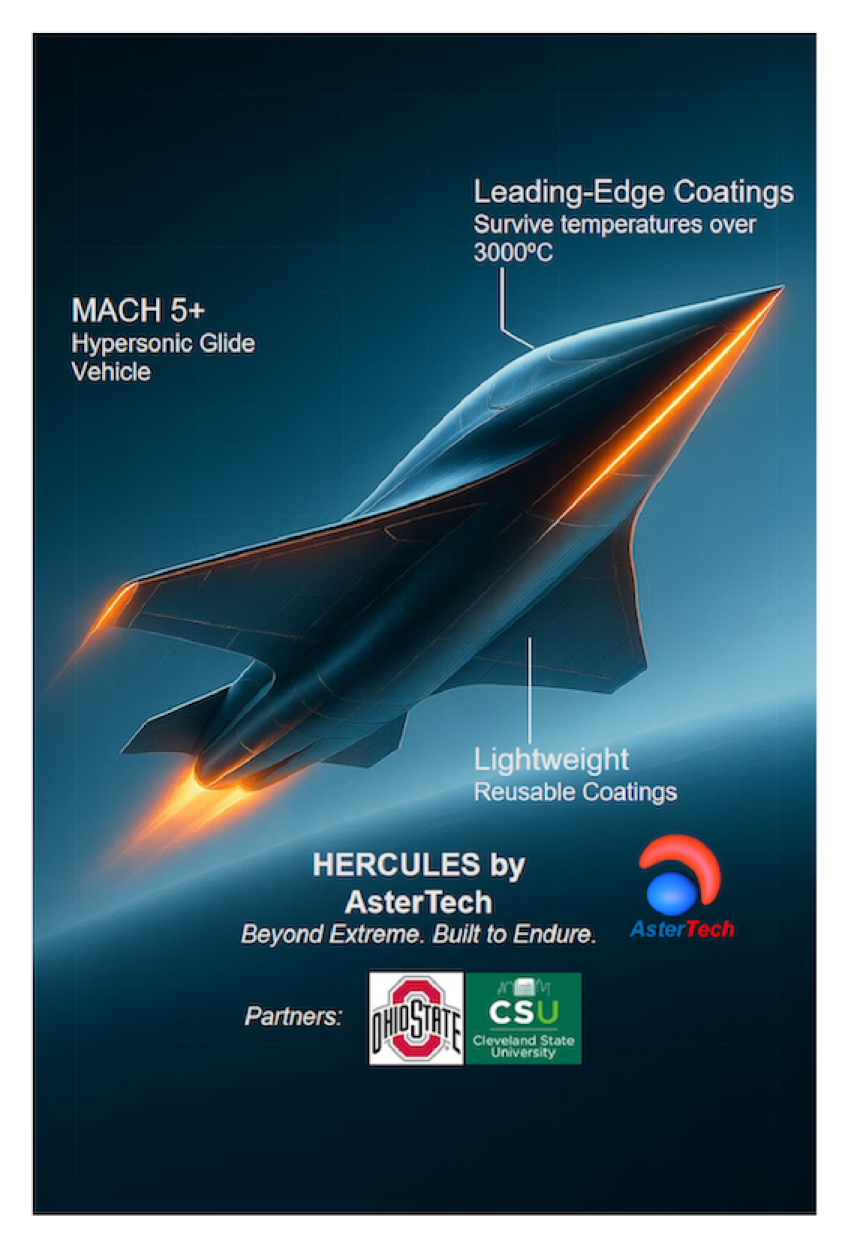

With a $1.25 million award from the Ohio Federal Research Network, the HERCULES project — short for Hypersonic Engineered Reusable Ceramic Ultra-Lightweight Enduring System — is developing a new class of ultra-high-temperature ceramic coatings designed specifically for reusable hypersonic systems.

The Ohio Federal Research Network is managed by Parallax Advanced Research in partnership with The Ohio State University and funded by the Ohio Department of Higher Education.

The project is led by AsterTech LLC, in partnership with The Ohio State University and Cleveland State University.

“HERCULES is about addressing one of the core limitations of hypersonic vehicles — how to survive extreme heat repeatedly without throwing hardware away after each mission,” said Dr. Santanu Bag, founder and President of AsterTech LLC and lead investigator for the HERCULES project. “Reusability is essential if hypersonic systems are going to move beyond demonstrations and into real operations.”

Addressing gaps in current materials

Most existing thermal protection solutions were designed for short-duration exposure or single flights. They tend to be heavy, brittle, and poorly suited for components that move or flex during flight. Many struggle to remain bonded to lightweight structures after repeated heating and cooling cycles.

“Today’s thermal protection solutions tend to be heavy, brittle, and optimized for one intense flight rather than many,” said Bag. “They struggle with surviving temperatures above 3,000 degrees Celsius, staying intact on moving parts like flaps and seals, and doing all of that repeatedly without major repair or replacement”

HERCULES is focused on developing coatings that can withstand temperatures above 3,000 degrees Celsius while remaining lightweight and durable. Unlike traditional approaches, the coatings are engineered to function as part of the structural system rather than as fragile outer layers.

The goal is to enable reusable hypersonic vehicles that are more affordable, more reliable, and faster to return to service.

Combining materials science and modeling

A key element of the project is the integration of advanced computational modeling with experimental testing. Researchers use simulations to predict how heat and stress move through coated components during hypersonic flight, allowing them to evaluate thousands of design variations before committing to physical tests.

“Computational modeling lets us ‘fly in the computer’ before we fly in the wind tunnel,” said Bag. “It allows us to predict where hot spots might develop and how stresses will build up during rapid heating and cooling, so we can focus physical testing on the candidates most likely to succeed”

That approach reduces development time and cost while providing insight into why certain designs succeed or fail. Early in the project, modeling predictions closely matched experimental observations, giving the team confidence that its simulations accurately reflect real-world behavior.

Advancing toward operational relevance

HERCULES is structured to advance the technology to Technology Readiness Level 5, a milestone at which component-level technologies are validated in relevant environments, demonstrating performance under conditions that closely resemble real-world use.

At that level, success means coating subscale parts such as panels, joints, or seals and testing them in environments that closely simulate hypersonic flight conditions. It also includes documenting repeatable manufacturing processes and integration methods that could support future transition into defense programs.

By April 2027, the team aims to demonstrate coated components operating under combined thermal and mechanical conditions representative of hypersonic missions.

Ohio’s role in hypersonics innovation

The project also highlights Ohio’s growing role in hypersonics research and advanced manufacturing. The state combines Air Force research capabilities, major engineering universities, and a network of small and mid-sized aerospace companies.

OFRN’s mission-aligned model connects those assets around specific federal needs, helping projects move more quickly from research to potential application. In the case of HERCULES, the program brought together industry, academia, and Air Force stakeholders to focus on a shared materials challenge.

“OFRN was designed to bring those assets together around real federal mission needs,” said Maj. Gen. Mark Bartman (ret.), executive director of OFRN. “Projects like HERCULES show how Ohio’s ecosystem can move advanced technologies from research into pathways that support operational relevance.”

While defense hypersonics are the primary focus, the coatings developed under HERCULES could have broader applications. Potential uses include reusable space launch systems, rocket propulsion, advanced gas turbines, and other industrial environments that involve extreme heat and harsh conditions.

By extending component life and reducing weight, the technology could improve efficiency and reduce costs across multiple sectors.

Shifting the hypersonics paradigm

If successful, HERCULES could help shift hypersonic systems from fragile, experimental platforms to reusable assets capable of sustained operations.

“Materials are often the limiting factor,” said Bag. “If you solve the materials problem, you open the door to faster, more reliable and more economical systems.”

With its focus on reusability, manufacturability and mission alignment, HERCULES represents a step toward making hypersonic flight a dependable tool rather than a one-time demonstration.

###

About Parallax Advanced Research & Ohio Aerospace Institute

Parallax Advanced Research is a research institute that tackles global challenges through strategic partnerships with government, industry, and academia. It accelerates innovation, addresses critical global issues, and develops groundbreaking ideas with its partners. With offices in Ohio and Virginia, Parallax aims to deliver new solutions and speed them to market. In 2023, Parallax and the Ohio Aerospace Institute (OAI) formed a collaborative affiliation to drive innovation and technological advancements in Ohio and for the Nation. OAI plays a pivotal role in advancing the aerospace industry in Ohio and the nation by fostering collaborations between universities, aerospace industries, and government organizations and managing aerospace research, education, and workforce development projects.

About the Ohio Federal Research Network

The Ohio Federal Research Network has the mission to stimulate Ohio’s innovation economy by building statewide university-industry research collaborations that meet the requirements of Ohio’s federal laboratories, resulting in the creation of technologies that drive job growth for the State of Ohio. The OFRN is a program managed by Parallax Advanced Research in collaboration with The Ohio State University and is funded by the Ohio Department of Higher Education.