Innovation

This program continues the development of soft switching power conversion technology using wide band gap power semiconductors. Soft switching reduces component and system-level electromagnetic interference (EMI) issues regardless of the application. The soft switching control approach enables parallel operation of disparate power generation sources. It offers high reliability, rock-solid system stability when powering unruly loads including constant power pulsed loads. This project will demonstrate soft switching in a 100-kW active rectifier.

Objective

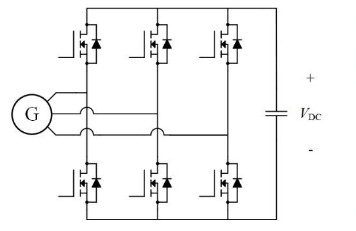

This program will demonstrate a 100-kW active rectifier constructed from three, modular, 35-kW isolated dc/dc converters that use soft switching technology. After several rounds of progressively harder testing, the final product will convert electrical energy from an aviation grade generator (~115 voltage alternating current (VAC)) to 270 voltage direct current (VDC) and be tested on a direct current emulator.

The technology developed with these objectives is relevant for isolated DC/DC converters used in aircraft, automotive, aerospace, microgrids, and telecommunications. Several design parameters can be adjusted to optimize the power conversion for reliability, size, weight, cost, etc. For this project, we demonstrate high power operation with low EMI using aerospace grade SiC devices.

Background

The maturation of high reliability wide band gap (SiC and GaN) power semiconductors has captured the imagination of power conversion engineers because these devices offer as much as 10X switching speeds over the best silicon switching devices. A common result is that power conversion equipment using WBG devices promises 2X weight advantage over Silicon-based conversion. On an aircraft, this can equate to 100s of pounds. The enthusiasm for WBG power conversion is tempered extensively when these power conversion components are required to meet EMI requirements (MIL-STD-461 or DG-160). Because SiC and GaN have such high dv/dt and di/dt characteristics, implementation of these devices requires additional passive components (inductors and capacitors) to meet EMI requirements, which negates the benefits of WBG components. The bottom line is, SIC GaN perform best when used with soft switching technology. Hard switching WBG devices offer disappointingly small weight advantages once EMI mitigation measures are implemented.